Additive Manufacturing

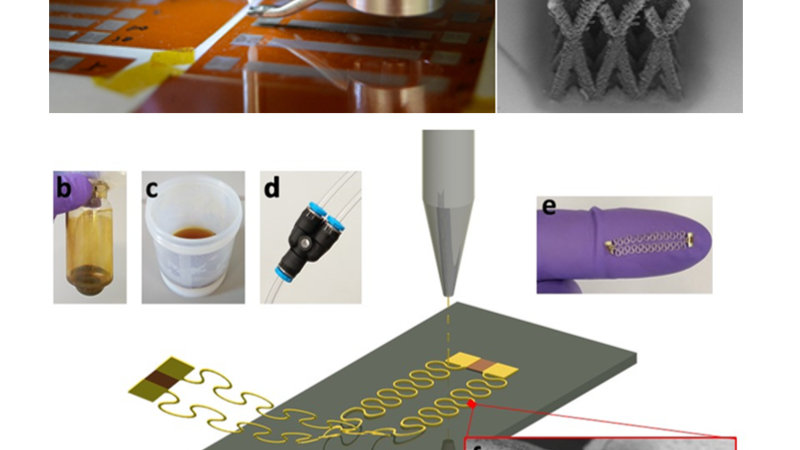

Additive manufacturing promises to be the future of device production. The ability to deposit material only where it is needed saves on both material costs and production time, whilst facilitating innovative device design. Aerosol jet printing is an advanced technique within this area, enabling fast deposition of fine scale features over a large area, including onto flexible substrates. Furthermore, while more traditional methods such as inkjet printing are limited to certain ‘inks’, aerosol jet printing can be used to deposit a wide variety of materials. Essentially, if a material can be dissolved, suspended or melted into a liquid with a thickness between that of water and motor oil, it can be printed with an aerosol jet printer. Our research group uses a state-of-the-art AJ200 aerosol jet printer from Optomec to fabricate both the passive and active components of sensors and energy harvesting devices. Our group develops proprietary inks of functional materials such as polymers, carbon nanotubes and thermoelectric materials. Combined with deposition of commercial metal nanoparticle inks, this allows entire devices to be printed. We are particularly interested in developing flexible and stretchable electronics for conformable functional devices.